Shaping: bringing your creations to life

Shaping means working a material to give it a particular form. In the printing industry, shaping refers to all the operations carried out after printing to give the final product its final appearance. Atelier Bulk specializes in embellishing printed objects, for which finishing is a crucial stage. It brings the finishing touch to each of your projects, giving them both functionality and uniqueness.

What is FAçonnage in printing?

As mentioned above, finishing covers the various operations carried out after printing. Shaping transforms the printed sheet of paper into a real object. It is given its final shape and functional appearance.

Converting encompasses a variety of tabletop techniques. These include table-top cutting, folding, gluing, padding, eyelet, elastic or ribbon fitting, and various binding techniques.

The aim of each of these operations is to transform the raw material into a finished product, ready for use or presentation.

discover the shaping techniques offered by bulk

Table work: folding, gluing, assembly

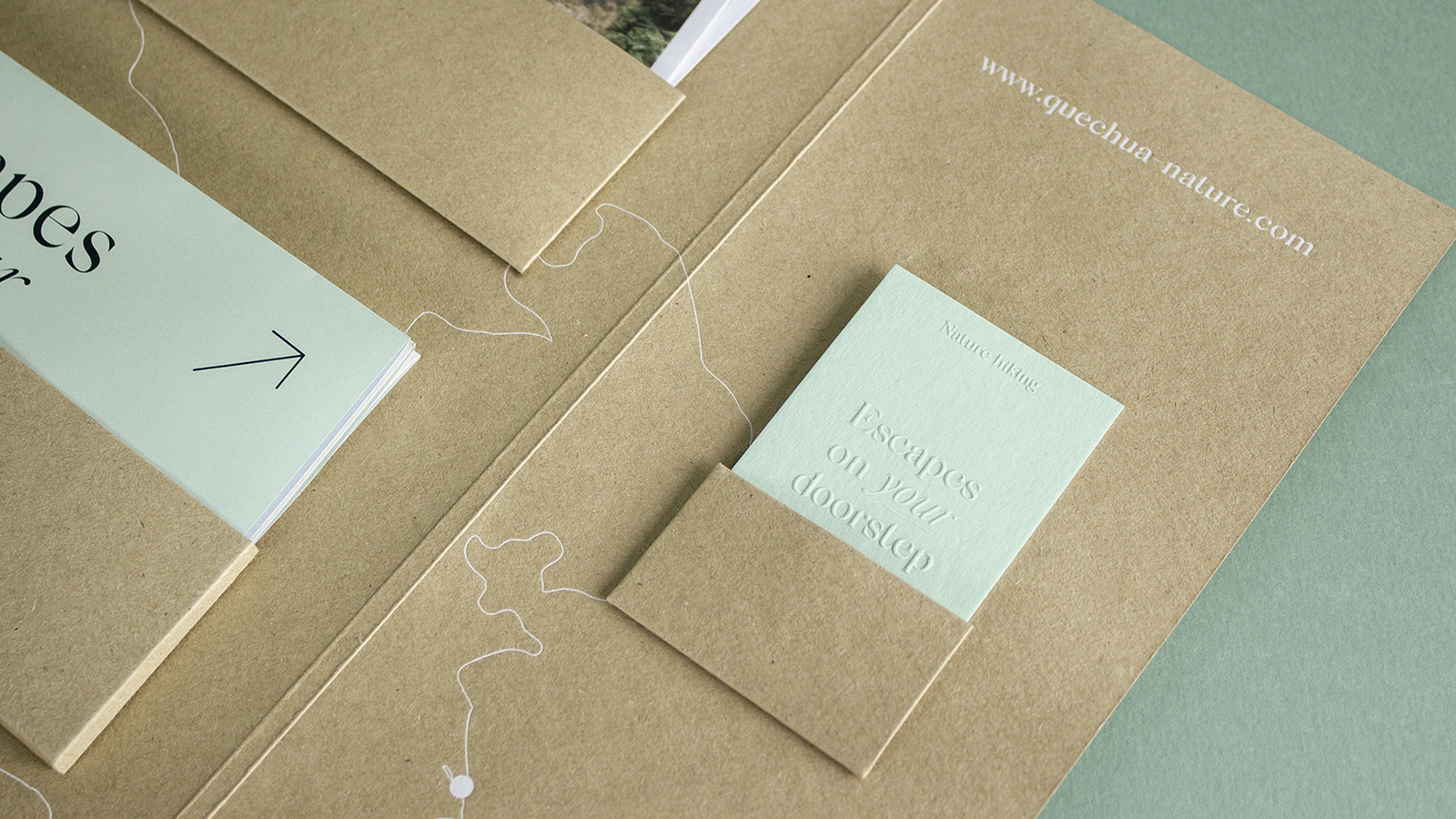

Table work is an essential technique in the printing finishing process, especially at Atelier Bulk. It involves manual operations carried out on a worktable using specially adapted tools. Our finishing craftsmen – known as “façonniers” – carry out meticulous tasks such as folding, gluing, mounting and other manual finishing operations.

Shapers start from the printed sheet of paper, flat, to give it its final shape. Through various cutting, folding and gluing operations, the object takes on its final shape. It becomes a box, a 2-panel menu, an envelope, a billfold, etc.

On the workbench, our craftsmen manipulate printed materials and stationery elements to ensure an impeccable final result. This step requires attention to detail, because every gesture counts. Our craftsmen are the guarantors of a perfect finish, meeting the exacting requirements of hotels, palaces and the great houses of luxury.

Table work is therefore an essential part of the production process in our workshop.

CONTRACOLLAGE

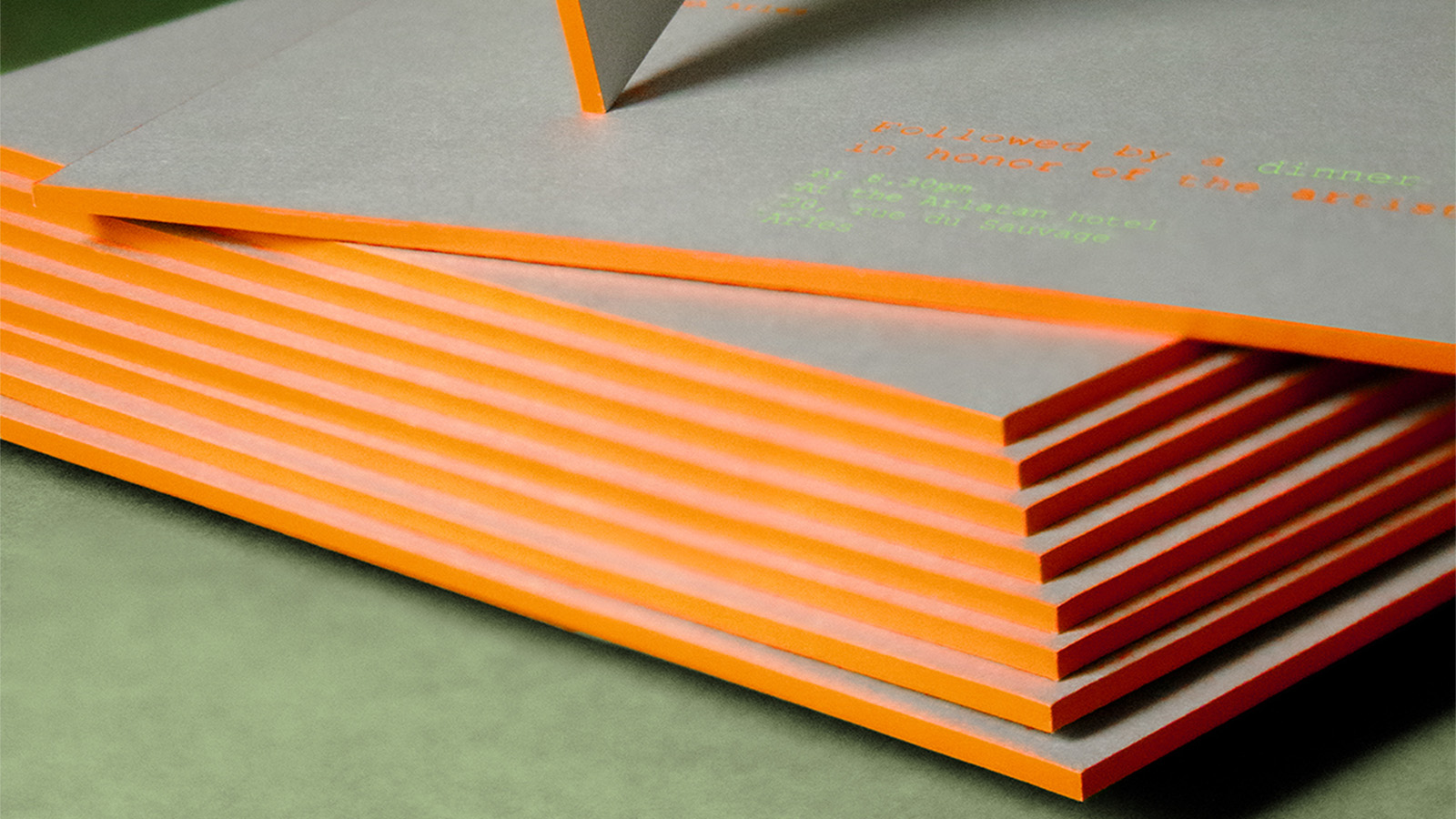

Laminating is a basic technique used in the printing industry’s finishing departments. It involves gluing together several layers of material, often paper or cardboard. This technique improves the rigidity, strength or aesthetic appearance of printed media. By multiplying the layers of material, the result is a heavier, denser object, giving a feeling of quality and a luxury dimension.

We regularly use the laminating technique to manufacture a wide range of products. The main uses are for event invitations, book covers, packaging, restaurant menus, and so on. It’s an effective solution for reinforcing printed media. Laminating enhances their durability while giving them a high-end, professional appearance.

Thanks to lamination, printed products benefit from improved strength and resistance to handling. Protection against tearing and folding is enhanced. What’s more, this technique gives the printed object a much more sophisticated and polished aesthetic presentation. Because it creates a thicker substrate, it is often combined with edge gilding.

REMBORDAGE

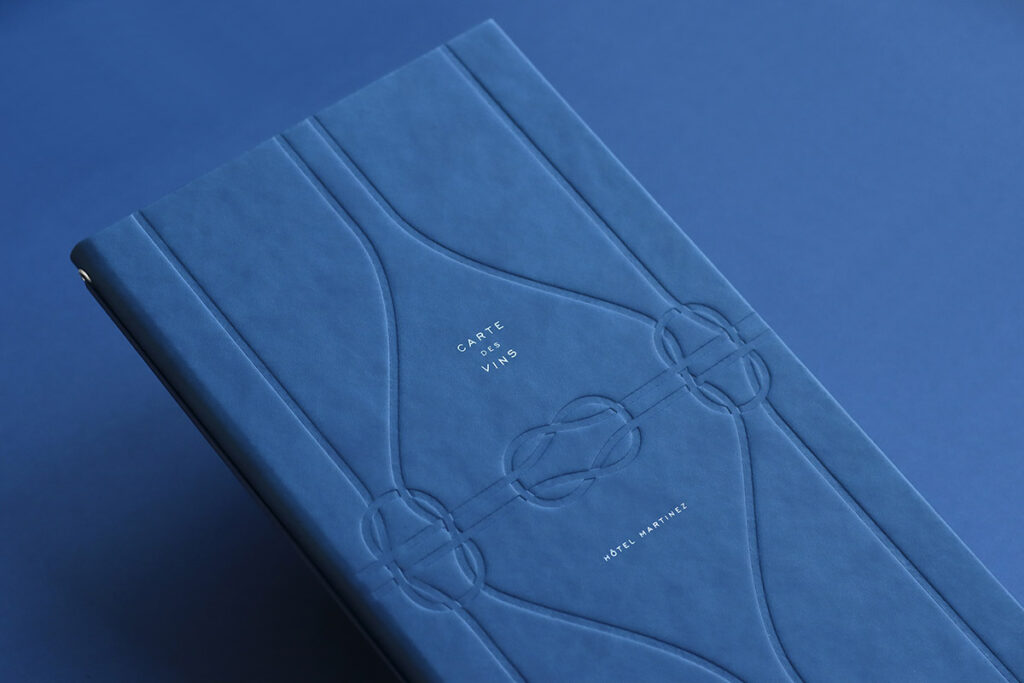

Embossing is a finishing technique used in fine printing to dress and embellish the covers of menus, books, boxes, cases, etc. This technique involves gluing a large sheet of paper or canvas to the surface and edges of a rigid support, often cardboard. The technique involves gluing a large sheet of paper or canvas to the surface and edges of a rigid support, often cardboard. This sheet is then carefully folded over the reverse side of the support, ensuring a smooth, even finish.

Before padding, the material can be printed, hot-stamped or embossed (as shown above). This technique is often combined with laminating to reinforce the rigidity of the substrate. Embossing adds an aesthetic dimension. This technique guarantees a solid bond with the support material, and therefore great durability for the object.

The materials commonly used for upholstery are diverse, ranging from paper and cloth to leatherette and other special materials. The choice of material often depends on aesthetics, functionality and customer preference.

Rembordiage is widely used in the manufacture of restaurant menus, luxury book covers, packaging, boxes and more. This technique adds a touch of sophistication to a wide variety of printed media requiring an elegant, resistant finish. It helps to enhance content and create a memorable user experience.

BINDING

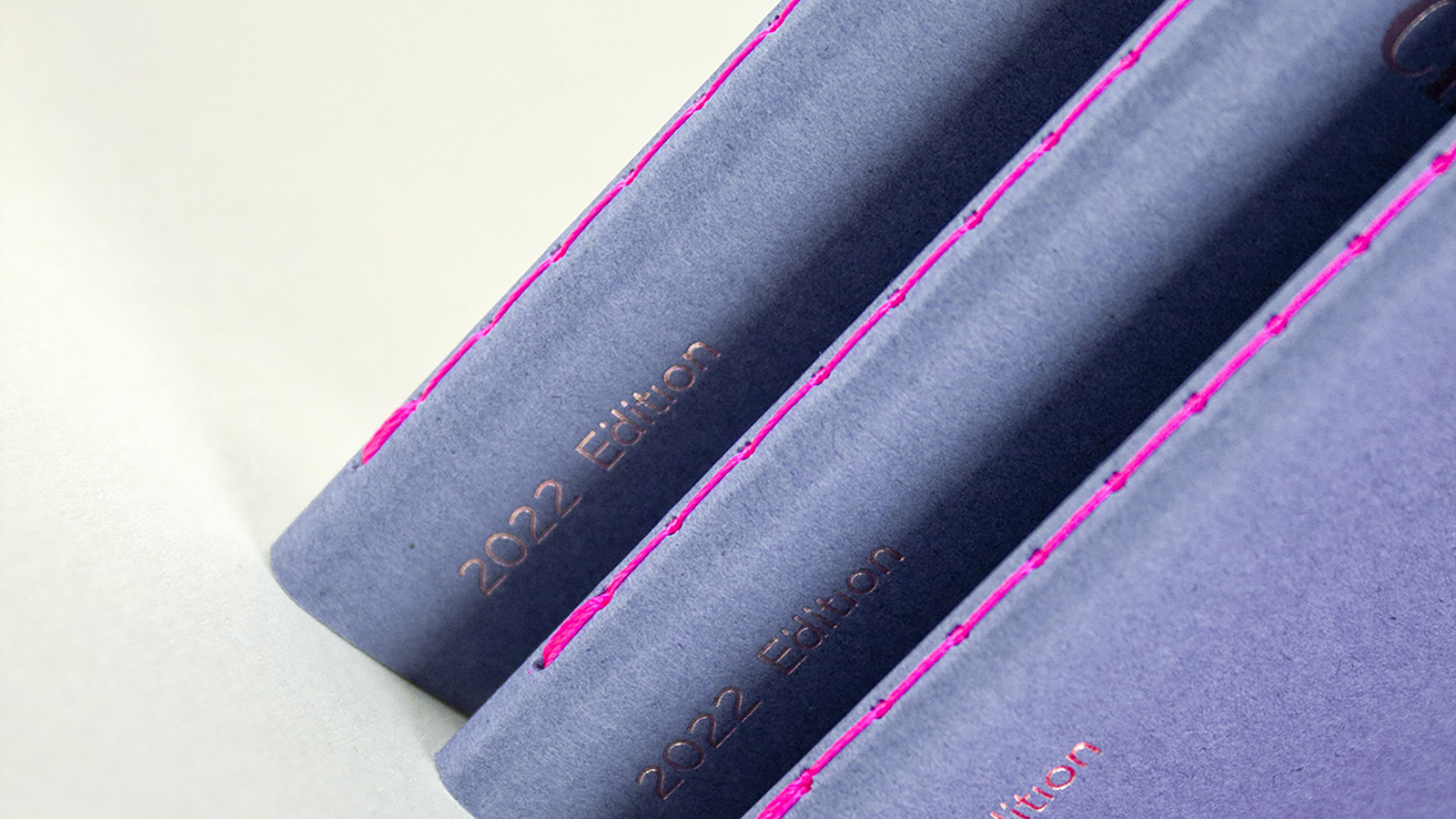

Binding is the set of techniques used to assemble the printed pages of a book into a coherent, durable whole. It plays a crucial role in the presentation and preservation of printed documents, ensuring their solidity and facilitating their handling.

Atelier Bulk offers many different techniques. If you’d like to find out more, please visit our web page dedicated to these binding techniques.

The main binding techniques include glued square back, Singer binding, stitched square back, spiral binding, Japanese binding, Swiss binding and many others. Each of these techniques has its own specific characteristics in terms of strength, aesthetics and cost. The aim, of course, is to choose the one best suited to each project.

Bindings are used to produce a wide variety of objects: notebooks, brochures, books, magazines, catalogs, photo albums, works of art. Each type of binding offers distinct advantages in terms of presentation, durability and practicality. This makes them an essential element in the production of a wide range of printed media.

LAYING RIBBONS, EYELETS, ELASTICS

At the end of the shaping operations, once the material has been folded, glued and recut, our teams of shapers add the final touch with accessories and finishing touches.

To slide and hold the inside pages of a restaurant menu, we’ll, for example, wrap the cover with a colored elastic band to underline the hot foil stamping. Alternatively, we can place eyelets through which we thread the elastics for added strength. These elastics are often crimped with hardware, the color of which can also be customized.

At the end of a luxury book or high-end menu, a ribbon bookmark can also add a touch of refinement.

Corner reinforcements can also be applied to strengthen the finished object.

In fact, the possibilities are limitless at Atelier Bulk. The aim is for you to concentrate on the design, and for us to find technical solutions to realize and enhance it.

Façonnage: Your Trusted Partner for Sublimating Your Printed Projects

At Atelier Bulk, we specialize in the art of finishing to create high-quality printed materials. Our team of printers bring your ideas to life and make your creations stand out from the crowd.

A variety of shaping techniques to meet your needs

Discover our expertise in a multitude of finishing techniques, from table-top folding, gluing and mounting, to laminating for added strength. We also offer padding for an elegant finish and binding to assemble your documents professionally.

We’re proud to offer a bespoke finishing service, tailored to your specific requirements. Whether you need ribbons, eyelets or elastics to add a touch of originality to your designs, we’re here to support you every step of the way.

Find a printer specializing in the finishing of printed projects

Trust Atelier Bulk to bring your printed projects to life with our exceptional finishing expertise. Contact us today to discuss your needs and find out how we can help you realize your most ambitious ideas.

Would you like to be inspired by the projects we’ve already completed? Take a look at our projects for notebooks,luxury editions and restaurant menus.