Embossing, fulling, debossing: add volume to your prints

Embossing and debossing are traditional embellishment techniques used in the printing industry. Instead of applying ink or a gilding film to the printing substrate, they create reliefs on the paper surface, offering a striking visual and tactile effect. Atelier Bulk specializes in embossing and debossing techniques. These methods are halfway between craft and art, where every detail counts.

How is embossing done?

To create a relief effect, the paper support is pressed between an engraved metal plate (tool) and its resin counterpart. The paper is then deformed to reveal the desired shape in relief: logo, text, frame, solid surface, textures, etc.

As well as hot foil stamping, Bulk is a specialist in embossing and debossing techniques. We master the engraving of embossing tools thanks to our 3-axis engraving machine. We also make the resin counterparts that give your embossing projects the volume you want. Our expert gilding and embossing craftsmen then adjust our Heidelberg presses to achieve the perfect embossing.

That’s how we master the variables involved in achieving the finest results. In this way, we meet the demands of our customers in the world of luxury and artistic creation.

The different embossing and debossing techniques

Paper embossing (embossing)

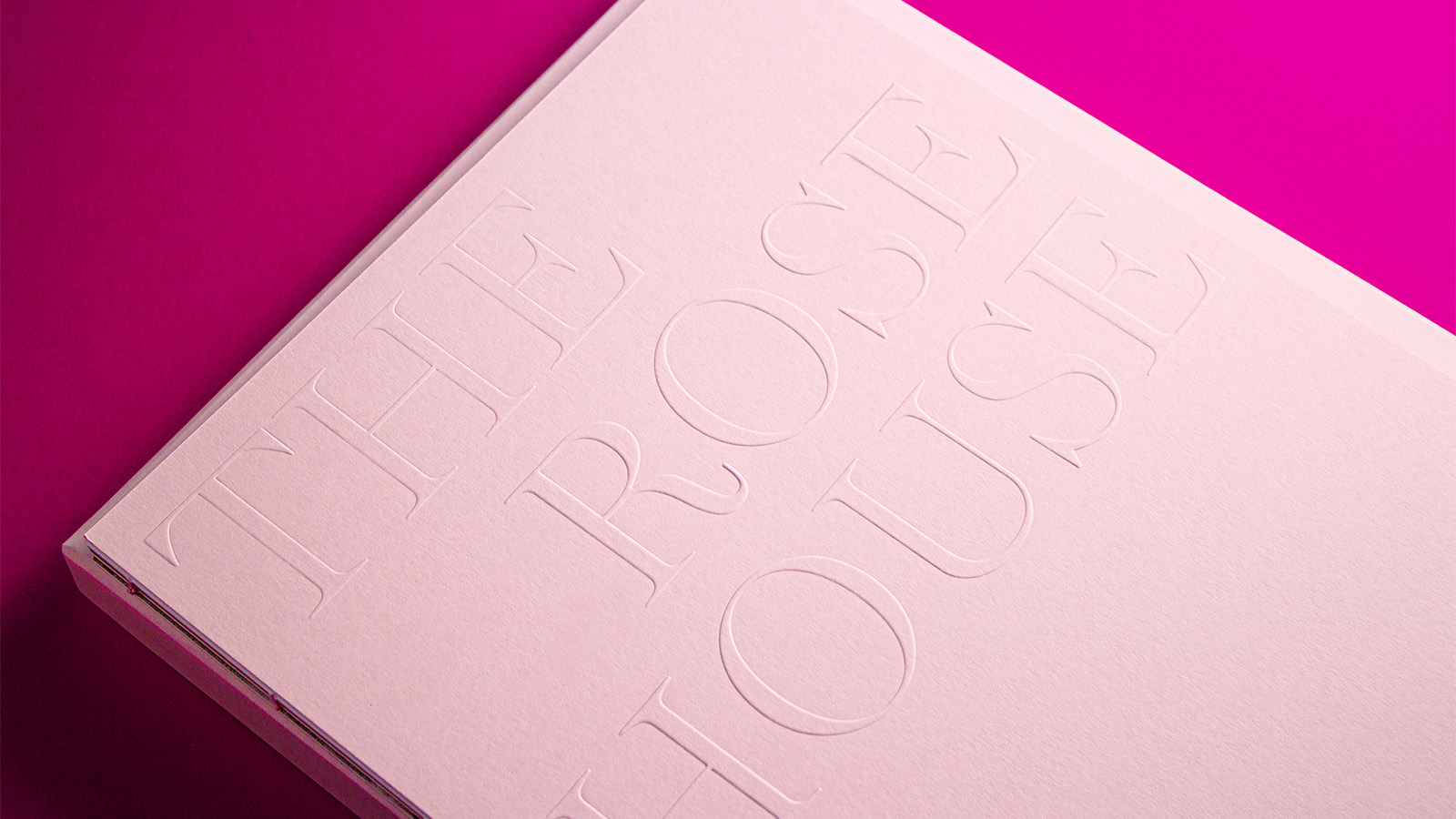

Embossing is synonymous with the term embossing. This technique raises a part of the paper support to create a relief, upwards, depending on the design.

For this technique, we press the paper support against a tool (engraved metal plate) heated to high temperature. The final effect creates a raised surface on the paper. This adds a palpable texture and distinct visual appeal to the raised part of the design.

Embossing is done “dry” when no color is applied. The result is a subtle, elegant texture, often used to add refinement to minimalist prints. If embossing is combined with foil stamping, we speak of curved gilding.

Debossing (crushing)

Debossing is a handmade printing technique similar to embossing, but creates an opposite effect by pressing the paper down to create recessed volumes in the substrate.

As with embossing, this is done using an engraved tool (metal plate). However, here we crush the paper instead of giving it volume. The result is a surface that’s depressed in relation to the rest of the substrate, creating unique tactile and visual effects.

In short, embossing raises part of the substrate, while debossing sinks it, offering a wide range of creative possibilities for bringing your prints to life.

These techniques impart an artistic depth and subtlety that push the limits of traditional printing. This is particularly true when they combine offset printing with hot stamping techniques.

Multi-level embossing

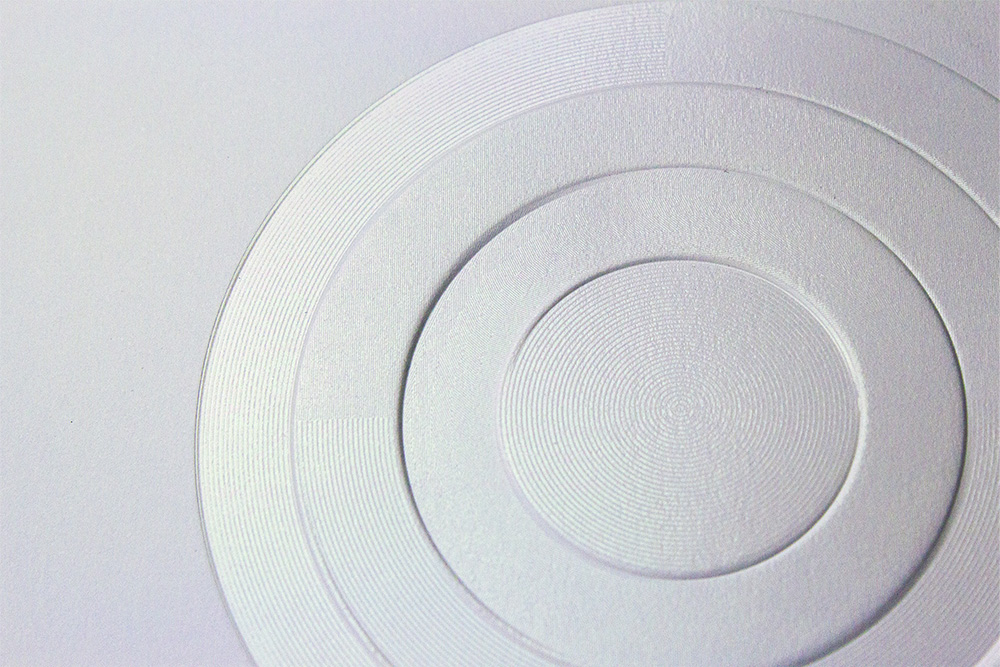

Multi-level embossing is an embossing technique that pushes the limits of creativity by introducing several levels of relief into a single design. With classic embossing, the substrate is raised on one level. In contrast, with multi-level embossing, we create multiple reliefs, adding a 3D dimension or refined texture to the printed object.

Multi-level embossing can combine both embossing and debossing techniques with respect to the initial substrate.

Where traditional embossing offers one dimension, multi-level embossing brings artistic depth with superimposed reliefs. This creates subtle plays of light and delicate shadows, adding exceptional visual richness.

It’s a technique that finds privileged applications in printing invitation cards, luxury stationery, high-end packaging and much more. It brings a touch of elegance and sophistication to any creation, capturing the essence of artistic luxury.

Curved gilding

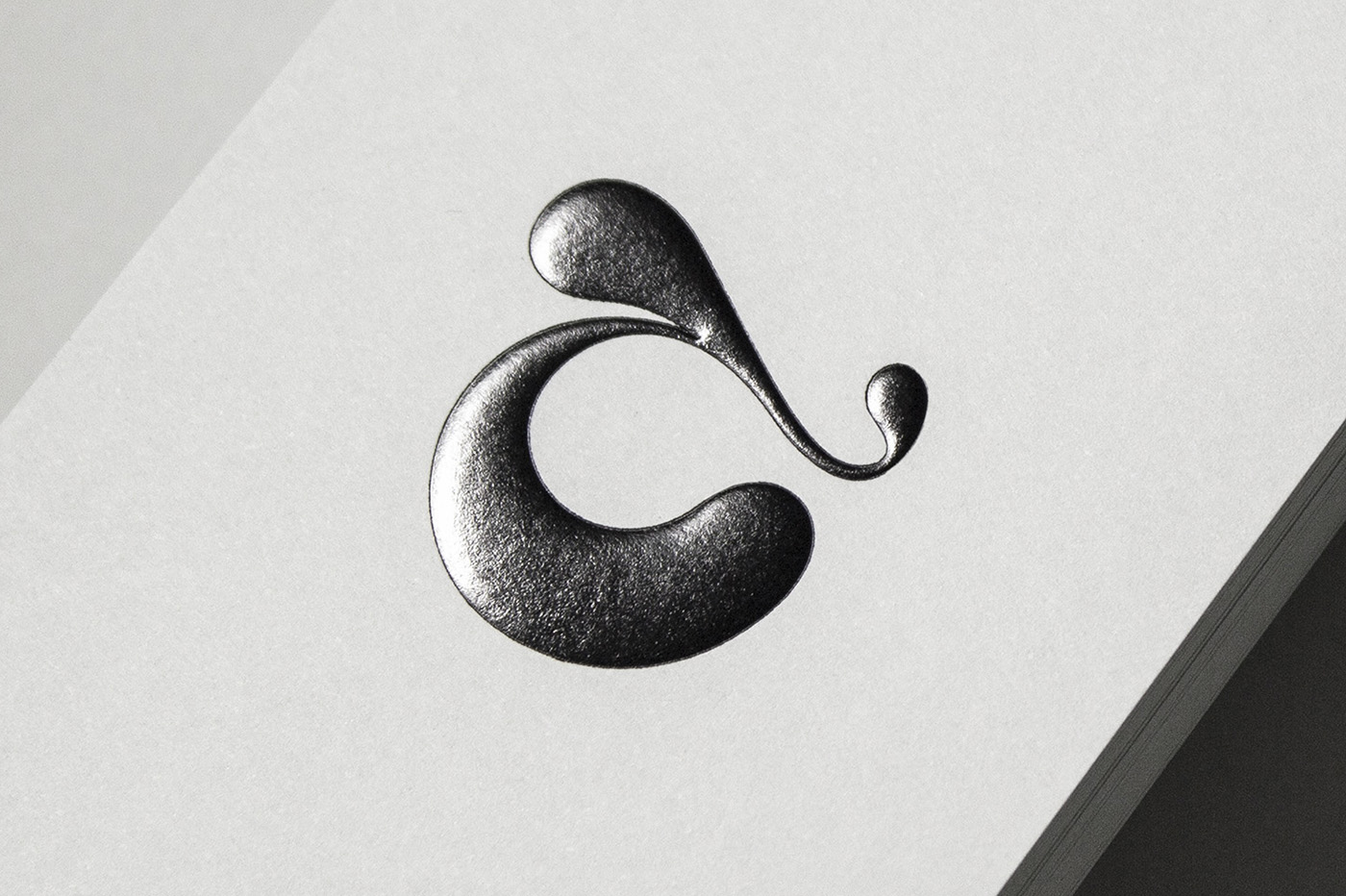

Curved gilding is an embellishment technique that combines the elegance of hot gilding with the subtleties of embossing or debossing.

Unlike dry embossing, which creates a relief on the paper without the use of color, curved gilding goes a step further by incorporating a hot stamping foil.

In the curved foil stamping process, the foil is pressed against the paper substrate using an engraved and heated tool. This process results in an embossed effect with added gloss, creating a striking contrast between the tactile texture of the relief and the luxurious sheen of the foil stamping, which can have a metallic, holographic, glossy, matte or colored effect.

Curved gilding thus offers a unique visual and tactile dimension, adding a sophisticated touch to prints such as business cards, invitations, or high-end product packaging.

Where can I find a printer specializing in embossing and debossing techniques?

With Atelier Bulk, your prints take on a whole new dimension. From our meticulous choice of materials to our mastery of the most advanced techniques, we transform every printing project into a work of art. Atelier Bulk, where luxury and precision meet printing.

Do you have a printing project requiring a debossing, embossing or debossing technique? Contact Atelier Bulk for a quote or feasibility study.