Artisans of luxury printing, we’ve been putting our know-how at the service of creation since 2015. Our expertise is nurtured by a balance between tradition and innovation, to offer you the very best in printing, finishing and finishing processes. We’re here to advise you and test your ideas with our prototyping service. To help you shape the future of printing and paper products.

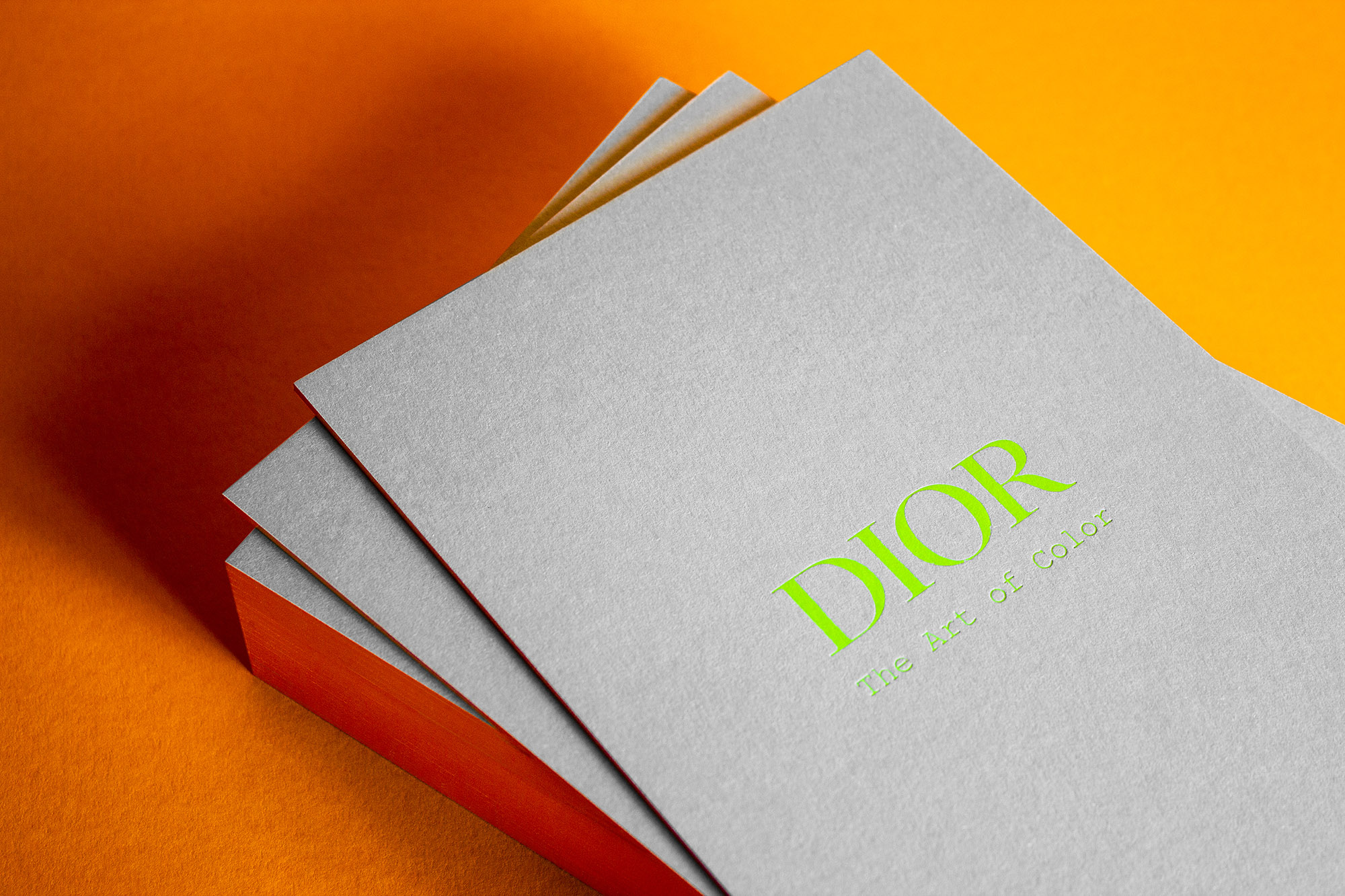

Hot foil stamping is our speciality, and the technique that helped us write the genesis of the Bulk adventure. Also known as hot stamping, this is a traditional printing process involving the application of a film (foil), usually metallic or colored, which is heated and pressed onto a paper substrate. This technique creates impressive visual effects such as reflections and diffractions. For high-end printing with a surprising effect, or to highlight an element in the design of a printed object, hot foil stamping stands out as an essential technique.

Offset printing remains a delicate technique, requiring a high level of expertise in terms of color rendering. Do you have a specific reference, whether it’s a Pantone®, a paper proof, the hue of a leather bag or the metallic sheen of a watch case? We’ve got the answer. Thanks to our colorimetry laboratory, we’re able to provide you with the right advice, and deliver offset prints that meet your requirements.

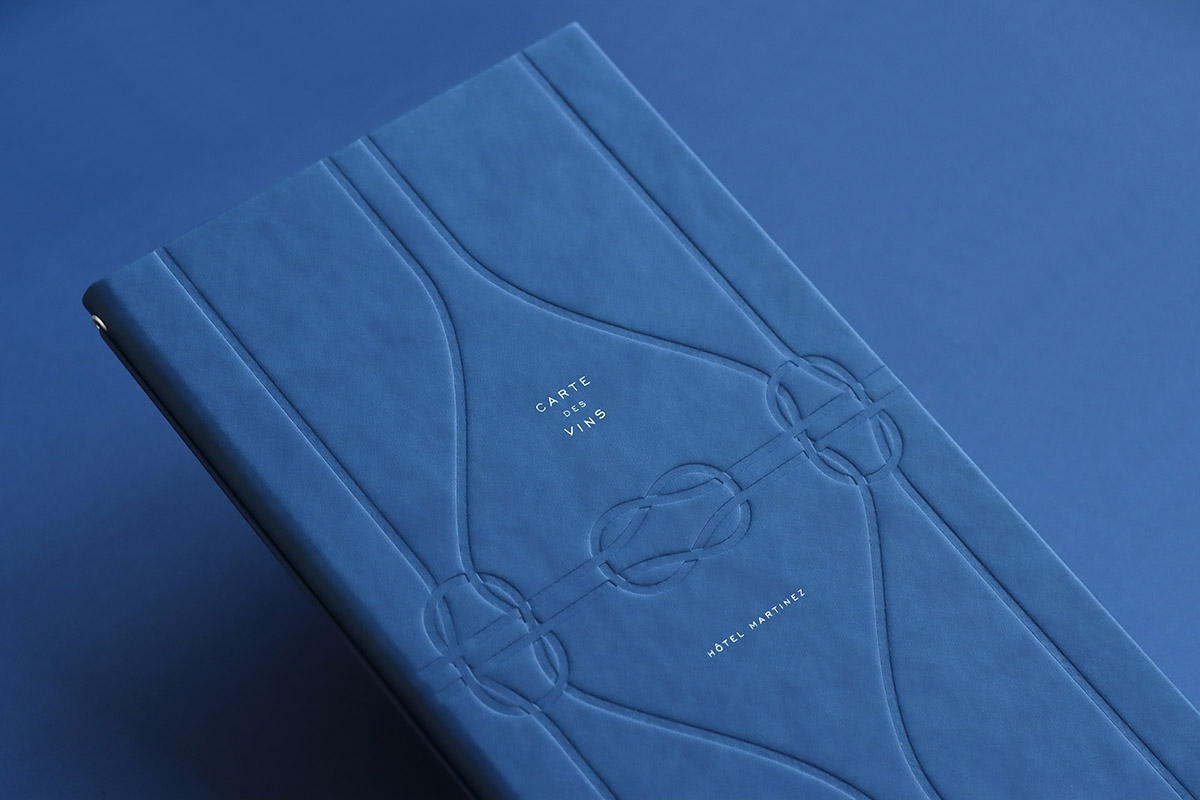

Since our creation, we have specialized in embossing and debossing techniques, two finishing processes traditionally used in luxury printing. With no ink or gilding film, these techniques are dedicated to embossing papers, offering a striking visual and tactile effect. Our embossing craftsmen master both the engraving of embossing tools and the pressure variables required to achieve the most exceptional results.

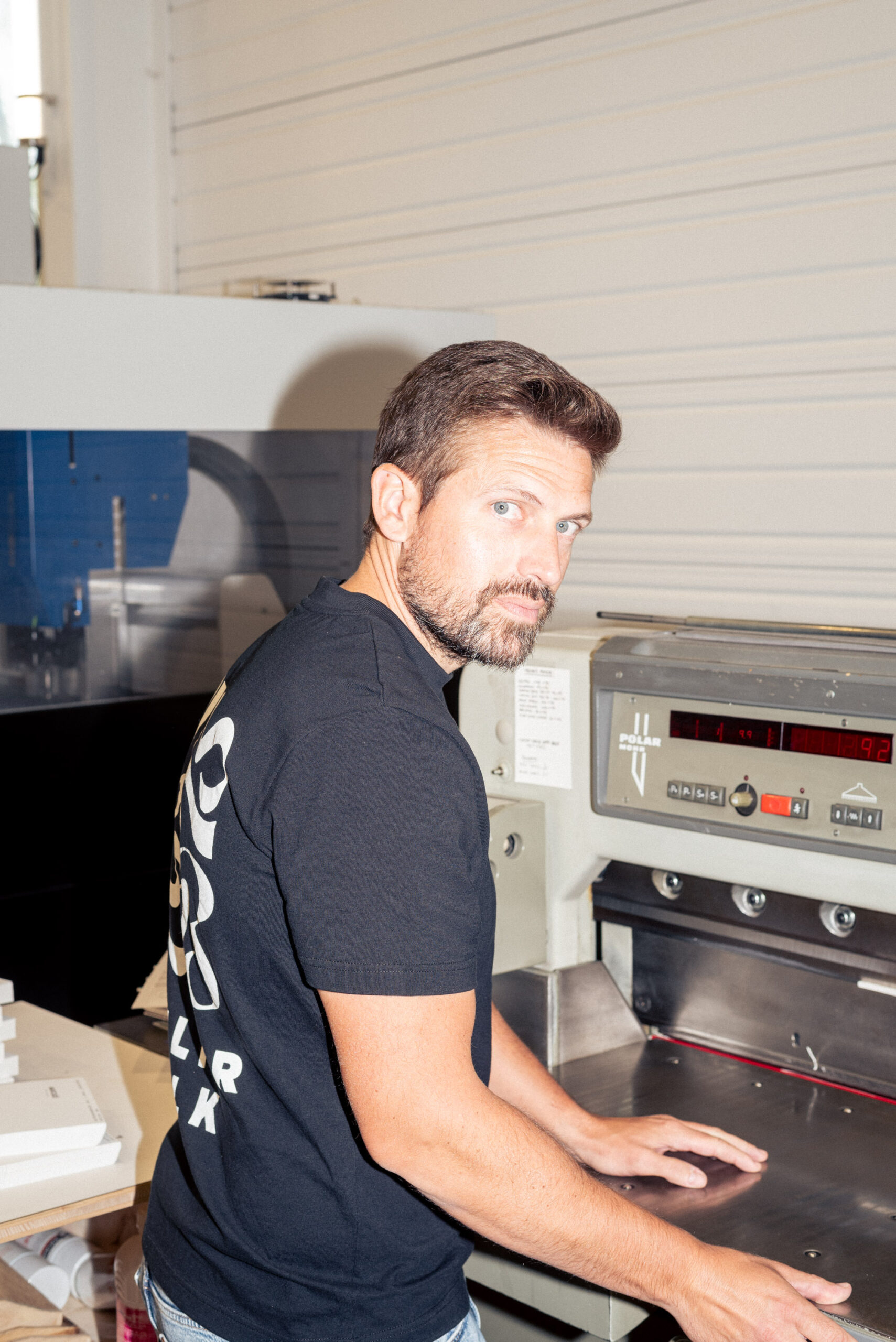

We integrate a range of customized cutting services for your printing projects, such as die-cutting (with cutting tool), digital plotter cutting, laser cutting, micro-drilling, and of course trimming for format cutting at the end of production. These different techniques enable us to create printed objects with customized shapes and precise contours. Custom die-cutting will also be an essential step in creating envelopes with personalized formats, folders or packaging projects with specific papers.

Finishing is the crucial stage that gives the printed object its final shape and appearance. Our team masters all the artisanal techniques that add the final touch to each project, revealing its character and functionality. Folding, gluing, assembling, binding, laminating or even stuffing: each of these manual skills transforms the raw printed substrate into a finished product, ready for use or display.

In a concern for the environment, we try to limit the impact of our activity. This involves optimal management of the waste inevitably generated by the printing business. For example, all our paper offcuts are reused for padding or protection for future projects. If offcuts are too small or cannot be reused, we sort them according to their properties: white paper, solution-dyed paper, cardboard. Once sorted, these scraps are periodically collected by our professional partner Azura Recyclage (ISO 14001 certified). The latter processes and transports the waste to recycling or reuse sites, following the example of local paper manufacturers. Our waste paper is then recycled to produce new materials. We’ve come full circle! For recurring orders, we also store and reuse marking tools. These marking tools are large engraved aluminum plates that we keep aside for future orders. For one-shot customers, we take the plates to a local partner who recycles them and resells the raw material to his customers.

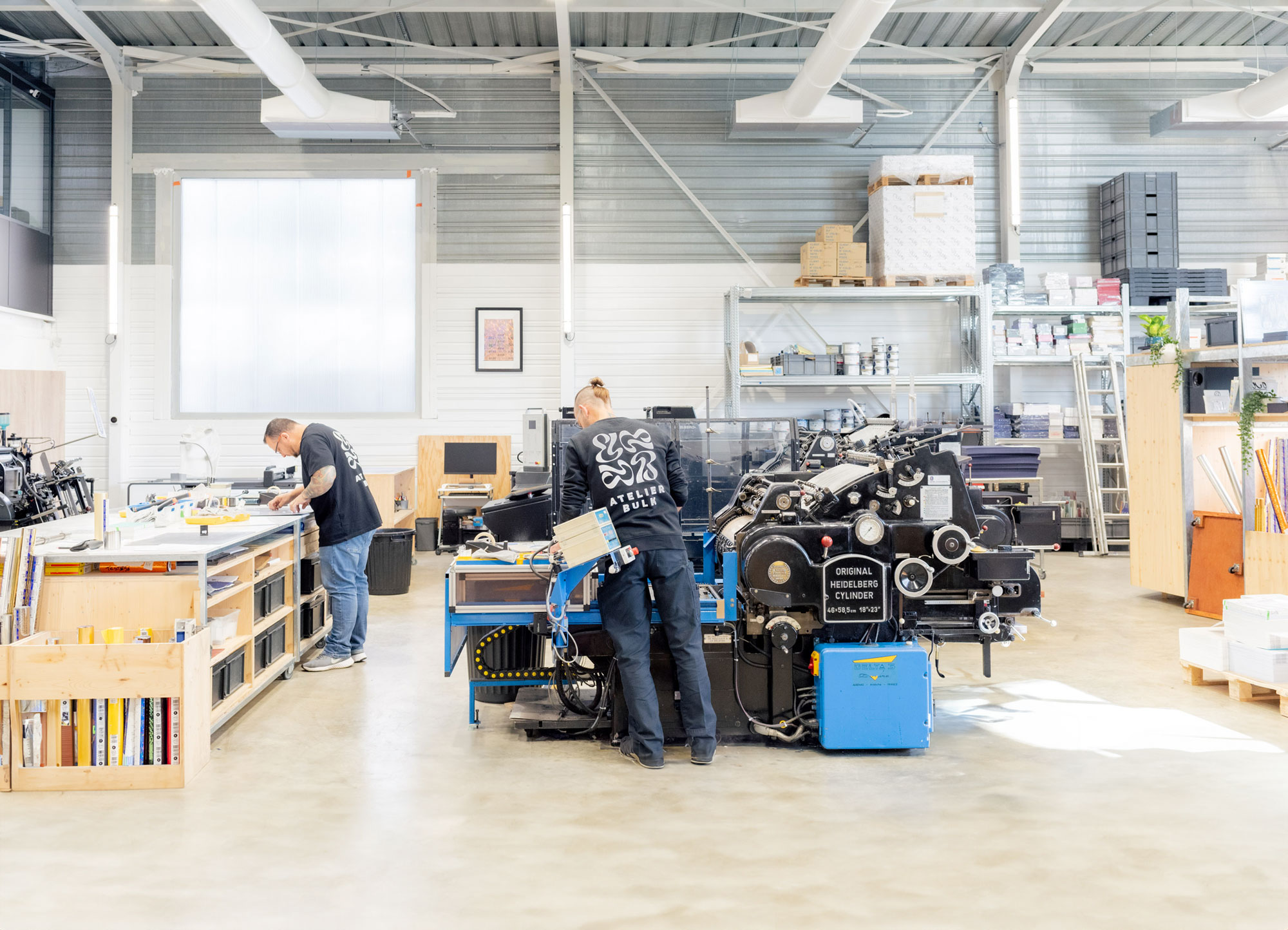

In 2022, Atelier Bulk moved to a new site in a landscaped business park. The building occupied by the workshop complies with RT 2012 thermal regulations. Our aim? To keep energy consumption below the ceiling of 50 kWhEP/m²/year (kilowatt hour of primary energy per square meter per year). To meet this ceiling, the entire building has been designed for minimum climatic requirements. To put it plainly: the workshop’s design and insulation ensure good energy performance and the most stable interior temperature possible, thus limiting our heating and air-conditioning requirements. Lighting is also taken into account: the workshop uses LED bulbs, and huge openings allow us to take advantage of the natural light offered by the south-western sun.

Many of you have asked us to trace the papers we use. The answer is simple: the papers we use are all FSC-certified. The FSC label guarantees that the paper is made from wood from sustainably managed forests. Paper pulp comes from specially replanted forests, and does not harm biodiversity. Finally, the wood is harvested with respect for the traditional rights of local populations. The 3 paper ranges we work with most are :

- Color 1802 (Procop): 29 100% recycled papers made in Europe. Certified by the Ange Bleu label, they meet stringent technical and environmental criteria: exclusion of hazardous substances, and use of 100% waste paper fibers.

- Keaykolour (Antalis): 48 papers in refined, complementary colors. The range is made from virgin fibers of FSC papers, and 5 papers are 100% recycled. In addition to the ecological aspect, this technique gives them greater gloss and a unique feel.

- Colorplan (G.F Smith): an emblematic range of FSC-certified creative papers created in 1936.

Refit papers, designed and produced by Favini and distributed by Antalis, are based on the principles of the circular economy, reusing waste from the fashion industry. The range is manufactured with 100% green, hydroelectric energy, self-produced by the Favini mill, making it carbon-neutral. The paper also includes 40% post-consumer recycled fibers and 15% wool or cotton fibers. The textile fibers used are of Italian origin and come from the carding, spinning and weaving industries. For the launch of Refit, Antalis asked Atelier Bulk to create a limited edition notebook focusing on eco-design and eco-printing. For its production, we focused on several ecological aspects:

- optimized notebook size to reduce paper waste,

- embossing tools engraved mechanically, not chemically,

- embossing of different papers using a single tool,

- the 3 cut-outs that create the overlapping effect of the 3 covers are made with a single tool + an interchangeable mesh system,

- The ink used is unique, created from cuttlefish ink and maizena for the binder.

In order to carry out the hot stamping and embossing operations, it is necessary to create a die called a “stamping tool”. This is an aluminum, magnesium or brass plate that is engraved with the desired design, in the manner of a print. Traditionally, these tools are etched with liquid chemicals that corrode and dissolve unwanted materials, revealing the desired design. These chemicals have an ecological impact. That’s why, since 2022, we’ve invested in a 3-axis mechanical engraving machine. This enables us to make our own marking tools, without chemical baths. Like a 3D printer, we use a simple engraving process with a set of more or less precise milling cutters to produce these marking tools. Not only do we gain in reactivity, precision and quality control… but our impact on the environment is drastically reduced. What’s more, our aluminum plates are entirely recyclable!

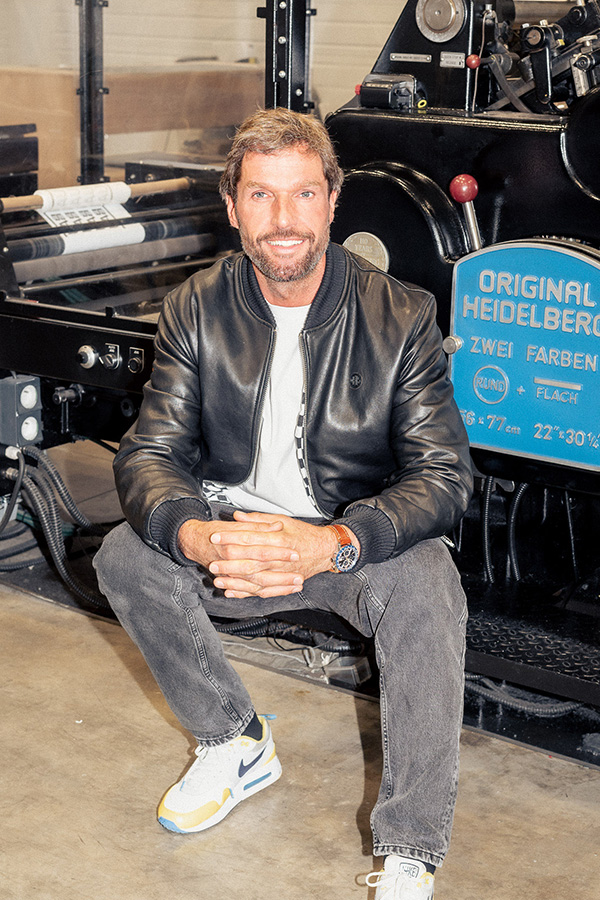

“In addition to its commitment to transforming an age-old craft into a contemporary practice, one of Bulk’s most important missions is to harness the boundless creativity of the world’s leading designers.” – viction:ary

Team

@Yann

Founder, Managing Director

@Fred

Project Manager / Estimator

@Lucille

Manufacturing Manager / Research & Development

@Antoine

Marketing Manager

@Nathalie

Administrative & Financial Manager

@Matthias

Workshop Manager

@Keavin

Typography / Engraving Manager

@Nicolas

Offset operator

@Christophe

Massicotier / Finishing Manager

@Marjorie

Shaping Manager

@Victoria

Shaper

@Morgane

Shaper (Freelance)